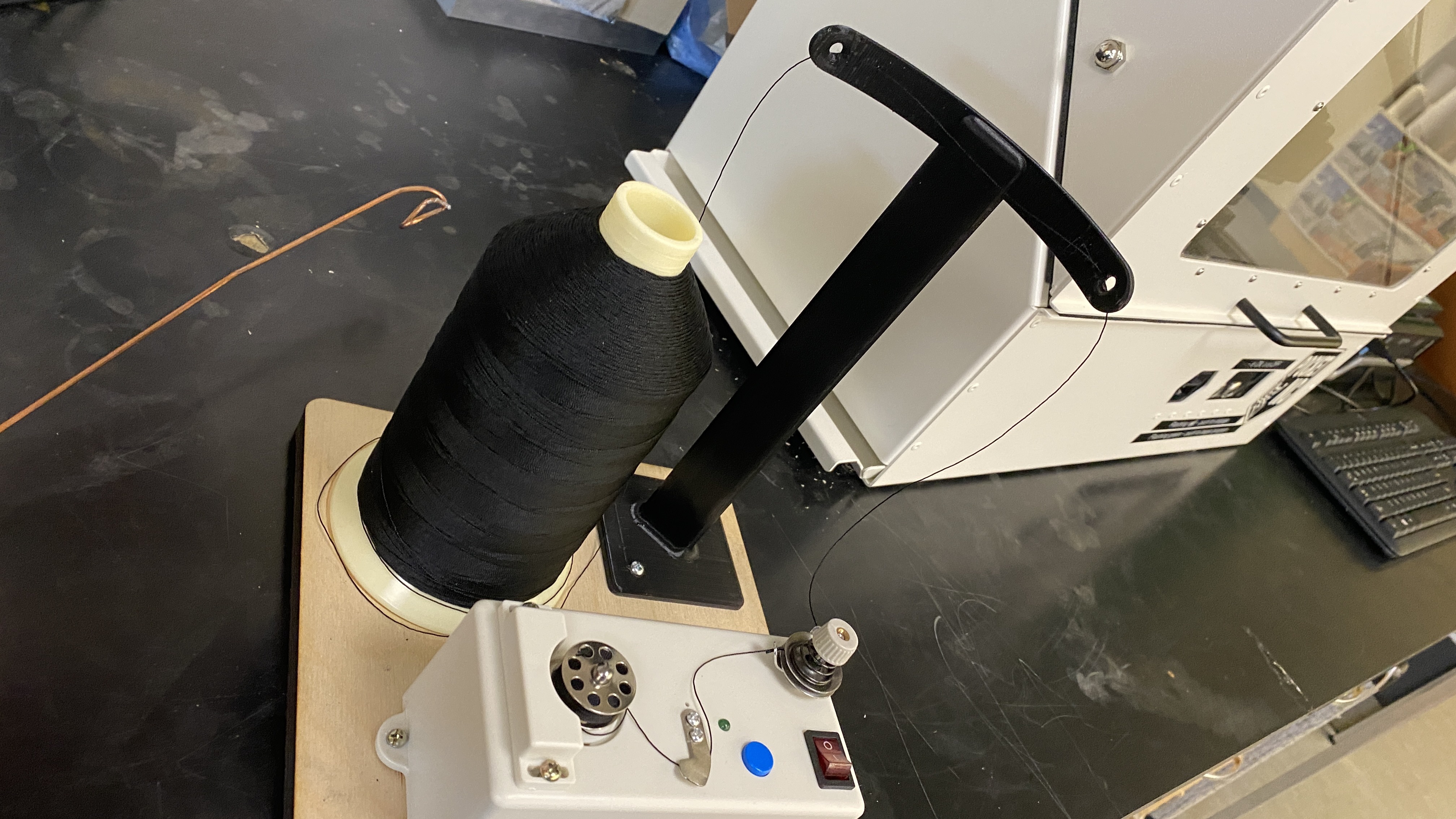

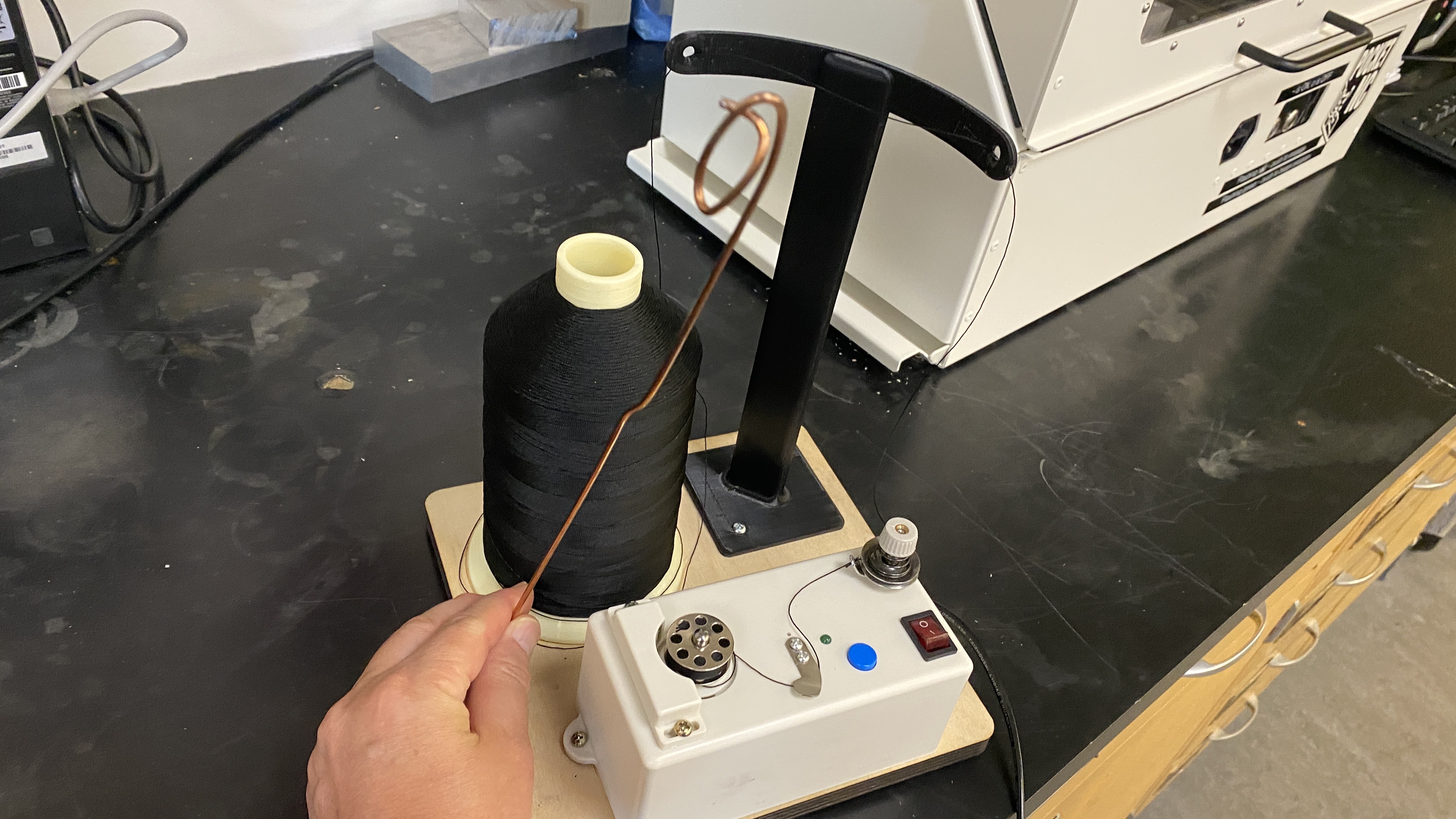

Our high speed bobbin winder came without an actual thread feeder. It also did not come with anyway to hold the spool of thread. I had been using a piece of copper wire and a block for the three feeder, but that proved disastrous at high speed.

I decided to design a proper thread feeder, that would take-up the thread over the spool ad then deliver it over the actual bobbin. Due to it’s height it had to be printed on our Ultimaker S5.

The base I cut out of 1/2″ plywood on our laser, that includes an angle block to hold the spool of thread.

The results, it works great and avoids having to use the sewing machine’s archaic bobbin winders.